When you think about buildings being demolished, the first thing that probably comes to mind is a huge crane with a wrecking ball, or explosives. These methods of demolition have been used for years by many demolition companies and have been handled by professionals working in the industry. However, even professionals are at risk of injury or incident when working to demolish a structure. But what if they didn’t have to be? That’s where demolition robots come into play! We’ll tell you all about demolition robots , and how using them can help to promote on-job safety.

What Are Demolition Robots?

Demolishing a large structure isn’t easy. It takes professionals handling equipment or explosives to bring a structure down. This can create a hazardous environment. Demolition robots are here to bear that risk instead. For a time, the demolition industry was hesitant to use automated machines, due to the chaos of a worksite when demolition is taking place. But as technology has continued to grow, demolition robots are here, and the demolition industry is embracing them.

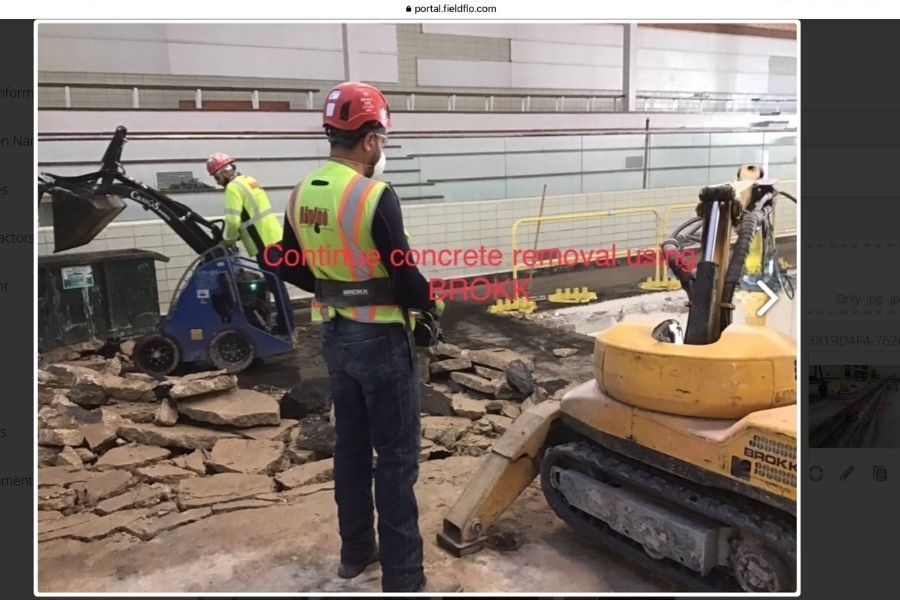

Demolition robots in construction are built specifically with the task of demolishing a structure or obstacle. They can be equipped with breakers, crushers, drills, or loader buckets to accomplish the job at hand. Demolition robots are usually sized so that they can navigate a building. To do that they have to be small enough to ride passenger elevators, go through normal doorways, or even take the stairs. To accomplish this, some impressive machinery is unnecessary to make the robot function correctly and take the place of a demolition worker.

When you begin to look under the hood of a demolition robot, you can see how impressive their construction is. Demolition robots can utilize many demolishing tools with their hydraulic-powered arms. These hydraulic-powered arms are backed by electric motors to keep everything powered and operating effectively. Due to their construction, they can pack quite a punch for their size. Demolition robots are then controlled by an operator who will control the robot’s movements remotely. Now that we understand what they are, it’s time to look at their role within the industry.

How Demolition Robots Fit in the Demolition Industry

Technology is constantly changing how many jobs operate. That is true even for professions that have typically been defined by manual labor. While there might have been a time when robots on a construction or demolition site were rare, that time has long passed. It’s now normal to see robots on multiple work sites. This is especially true for demolition robots.

Robotic demolition now makes up most of all construction robots that are sold. However, that does not mean they are cheap. Due to the technology that is being used and their construction, demolition robots carry a hefty price along with them. You can expect prices for one of these robots to start around $100,000 dollars for robots that are on the smaller side. As the size of the robot increases, you can expect the price to go up as well. Those who manufacture demolition robots claim that the high price tag is worth the cost due to the many advantages these robots can provide. Let’s look at the ways demolition robots have helped change the demolition industry.

Advantages of Demolition Robots

For demolition companies to justify the high cost of demolition robots in construction, they of course come with a variety of advantages. Whether it’s creating a safer workplace environment or for their efficiency, companies are willing to pay the price. Let’s take a closer look into the advantages of demolition robots.

On-Job Safety

The original goal of demolition robots was to get workers out of potentially hazardous conditions. So, they were constructed to offer the biggest benefit to the workplace, in this category. By operating remotely, it allows a human operator to stay at a safe distance from any hazards. Another aspect that many don’t think about is that the robots are saving human workers from the wear and tear on their bodies. As anyone who works in manual labor can tell you, the days begin to add up, and it’s your body that takes the punishment.

Portable

These Robots are extremely portable for the amount of work they can produce. Demolition robots are tasked with navigating a variety of structures. They are constructed with this in mind. So, you can expect a demolition robot to be able to fit through standard doorways, climb stairs, or even ride the elevator. To accomplish these tasks, they must be a size that is easily portable from site to site.

Efficiency

Demolition robots are extremely powerful for their compact size. They can break structures down that vary greatly in size. They are also expected to be able to break concrete slabs—usually far beyond the size or weight of the demolition robots. The robots can also be used to complete projects at a faster time frame. Since demolition robots do not tire like humans, you can expect the pace of work being completed to be the same from start to finish.

Return on Investment

Demolition robots offer a return on their investment in multiple ways. Whether it’s helping to support your workforce, or time saved by a robot’s ability to get the job done quicker—demolition robots begin to earn their purchase.

So, what now? You realize you’re in need of professional demolition services, and now you know all about demolition robots for getting the job done. But who should you contact to trust with your demolition? Well,

Alpine Demolition of course!

Alpine Demolition

We have taken a few moments to walk through the steps you need to take before moving forward with a deconstruction or demolition project. This is an exciting time for you and your organization, and we are eager to walk with you through this process each step of the way.

At Alpine Demolition, we make several guarantees to our clients. We guarantee safety, modern technology, sustainable practices, and care for the community and environment where your project is located.

Contact us today by clicking

here to ask questions or begin a bid form. Or call us at 630-761-0700 with any questions you have about your upcoming demolition project.

Remember, the first step you need to take before a demolition project is deciding whether deconstruction is the right choice for you and your group or organization. We would love to talk through all the options with you to help you make a stress-free decision.

3515 Stern Ave, St. Charles, IL 60174

(630) 761-0700

Office Hours

Mon - Fri: 8:00 am - 4:30 pm

Sat - Sun: Closed

Website imagined and executed by RivalMind.

Quick Links

Stay Connected with Alpine:

Sign-up to receive regular news updates from Alpine Demolition.

Newsletter Email

We will get back to you as soon as possible.

Please try again later.